Their unique geometry allows hat purlins to carry more load with less material, making the structure stronger and lighter — saving on transport and installation costs.

Hat purlins distribute stress better, making them ideal for projects in high-wind zones — like coastal regions or open fields.

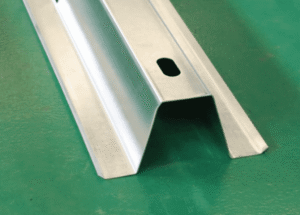

Pre-punched holes and consistent shapes lead to quicker alignment and bolting on site, reducing labor time.

With less steel required for the same strength, you get better cost-efficiency without compromising safety.

Project consultants prefer hat purlins for rooftop solar and visible installations due to their clean, symmetric look.